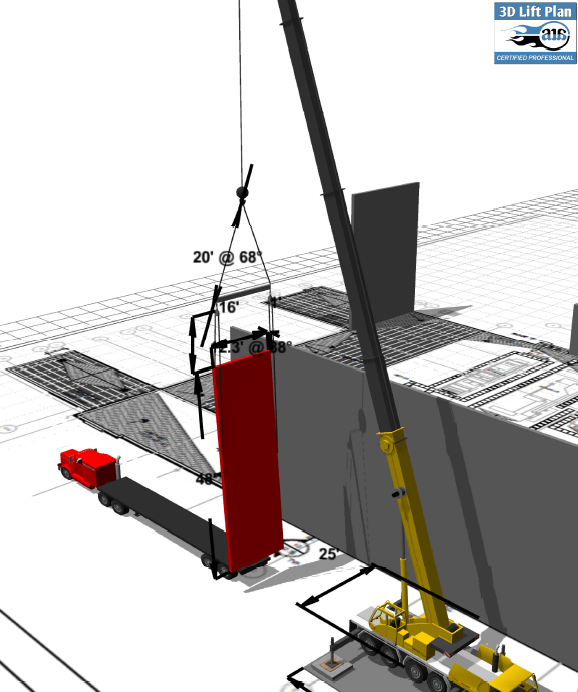

Forestry Operations and Similar Activitiesġ4.8 Boom extension and load radius indicatorsġ4.16.1 Certification following misadventureġ4.33 Fire extinguisher EQUIPMENT OPERATIONġ4.39 Contact with loads and structures ġ4.49.1 Communication between equipment operatorsġ4.53 High voltage electrical conductors BRIDGE, GANTRY AND OVERHEAD TRAVELLING CRANESġ4.58 Direction markings PNEUMATICALLY POWERED HOISTS AND WINCHESġ4.60 Electric hoists MANUALLY POWERED HOISTSġ4.62 Crank handles MOBILE CRANES, BOOM TRUCKS AND SIGN TRUCKSġ4.65 Cranes on floating supports ġ4.94 Counter jib MISCELLANEOUS MATERIAL HOISTSġ4.95 Standards CONSTRUCTION MATERIAL HOISTSġ4.106 Travel and load limit switches ġ4.107 Erection and maintenance ġ4.108 Operator qualifications ġ4.109 Operator responsibilities ġ4.111 Testing safety and control devices ġ4.131 Operator qualifications ġ4.132 Unattended controls SCHEDULE 14-A Diving, Fishing and Other Marine Operations Ladders, Scaffolds and Temporary Work Platforms Personal Protective Clothing and Equipment Noise, Vibration, Radiation and Temperature The CG must always be at the center of the lifting points.Occupational Health and Safety Regulation There was no means of keeping it stable once gravity started to act on it. In photo above, when the chocker was removed from the actuator, the load became eccentric and the CG was outside the anchor points. Never put on lifting points only on one side of the CG. Always ensure lifting points are directly above or equally spaced on either side of the Center of Gravity (CG) of the load. Especially, when the assembly is completely unstable and relying only on friction to keep it from rolling.Ģ. If the chocker placement is not correct, lower the load and reset the chokers when the load is on the ground and stable. Fortunately, no personnel were injured, but materials were damaged.ġ. They changed their rigging configuration that was holding the assembly upright without securing the load and the assembly tipped over. In 2015, a Contractor was attempting to up-right a prefabricated valve assembly. A Critical Lift Plan is required when the criteria (listed above) are met for a Critical Lift.īelow is an example of a Critical Lift Plan:Ĭomplex Lift: A non-routine crane lift requiring detailed planning and unusual or additional safety precautions. Critical Lift: A lift that exceeds 75 percent of the rated capacity of the crane or derrick and/or requires the use of more than one crane or derrick.īefore making a critical lift, a pre-lift meeting is conducted to ensure all involved parties understand all aspects of the lift.

0 kommentar(er)

0 kommentar(er)